The concept of Finishing 4.0 has been around for a little more than two years. Today I’d like to take the opportunity to tell you a bit more about our development strategy. What exactly does this term mean?

In the print finishing business it has mainly been thought of in terms of production methods, i.e. perfect binding, saddle stitching, thread sewing, etc. However, because the various machines – and thus the processes as well – are increasingly networked, we have to look beyond the individual segment. The changes underway in the printing industry have resulted in challenging processes for print finishing. The following developments play a role in this regard:

- Digital printing with better performance and quality

- You need solutions for both long and short runs of as little as runs of one

- Products must be personalized and customized

- Delivery times are constantly falling

Have you experienced any of these issues at your company? If you’re a printer or bookbinder and you want to be successful under the above-mentioned conditions, then you need intelligent systems, machines and software in order to meet all of these requirements and, most importantly, to make full use of the current opportunities.

Seamless communication is required

First and foremost having the right printing technology is, of course, crucial. But what happens next with the printed paper? The requirements related to print finishing have changed significantly. It must be highly flexible, reliable, expandable, simple (in terms of operation) and efficient. There is also a high level of automation, the workflow and reporting. The level of complexity is even greater if each product being produced is an individual product – with the keyword here being “variability”. And, finally, starting production should be possible with as little manual intervention as possible. In the ideal scenario, this would be done with a touchless workflow.

How digital workflow works on the Primera MC saddle stitcher

This is where the Finishing 4.0 production concept, which is based on the ideas behind Industry 4.0, comes into play. The biggest challenge here is ensuring seamless communication between the machines and all of the elements involved. You might think that two Muller Martini machines in the same room would automatically understand one another as well. It’s not that simple, unfortunately. The machines can understand one another to an extent – but not completely. And, as we all know, the devil is in the details.

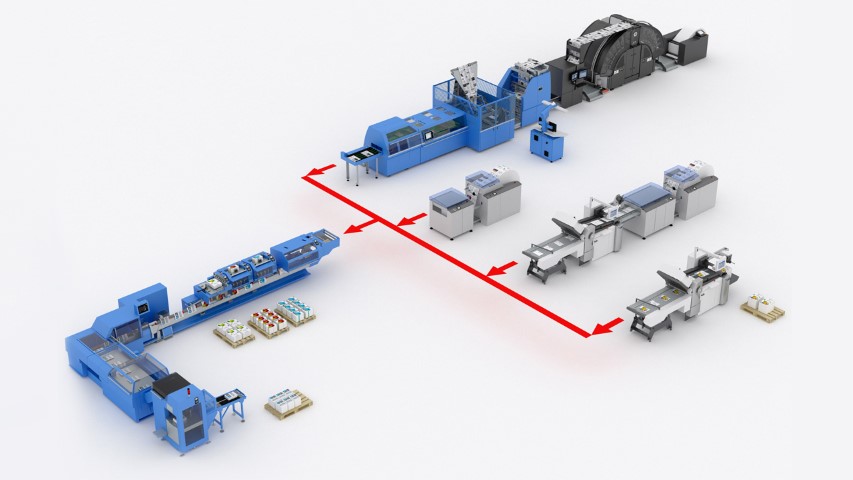

In order to enable logical and comprehensible production, the machines must be highly integrated. And the more the machines (have to) learn from one another, the more complex the integration becomes. As part of the “Finishing 4.0” initiative, we put these ideas into practice, taking account of the printing process where possible. It doesn’t matter if you manufacture offset, digital or hybrid print products. The end-to-end workflow, from file to finished product is now a reality and will be modified and enhanced on a continuous basis.

The specific advantages for you:

- Lower changeover times

- Lower personnel costs

- Less production waste

- Reduced amount of faulty input

- Faster market introduction

- And, finally, satisfied end customers!

If you don't know yet exactly what the future holds: Hybrid systems from Muller Martini can be flexibly expanded with a digital option.

If you’re still not sure what lies ahead for you: hybrid systems

Companies that only print using offset printing can install a combined system of saddle stitchers, perfect binders and booklines capable of both conventional and digital production or expand their system to include a digital option. You can then use the system for digital sheetfed printing, digital roll-fed printing or even a combination of the two applications. And you can also continue to use conventional offset printing.

- This will allow you, for example, to quickly change over for a rush job of 100 copies and then switch back to the original production order without a significant loss of time.

- You will be able to offer your customers the same high production quality for digitally printed products as with offset printing.

Optimized profit potential

At the end of the day, Finishing 4.0 is all about ultra-efficient print finishing and – for you – higher profits. The most important factor here is that the Finishing 4.0 solution meets your needs in full. I will explain the extent to which a high level of automation and a seamless workflow play a role in a future blog post.

Would you like to learn more about what role automation and networking play in Finishing 4.0? Then read part 2 of our Finishing 4.0 series.

Until then!