Producing offset and digitally printed books, gathering or preparing the next job on the gathering machine – and ideally as much as possible at once. The versatile finishing systems from Muller Martini make this possible.

Our worldwide customers appreciate our solutions not only for their modular design, which allows them to respond to new market requirements at any time and expand equipment at a reasonable cost to achieve a high level of investment protection. Many are also impressed by our systems’ flexible application possibilities.

They are becoming increasingly important as magazines, brochures and books are becoming ever more variable while having ever lower print runs, thanks to the wide range of options offered by digital printing. If our customers can carry out two work steps simultaneously on the same equipment, this naturally increases the throughput and profitability of the individual production runs and thus the profitability of the company.

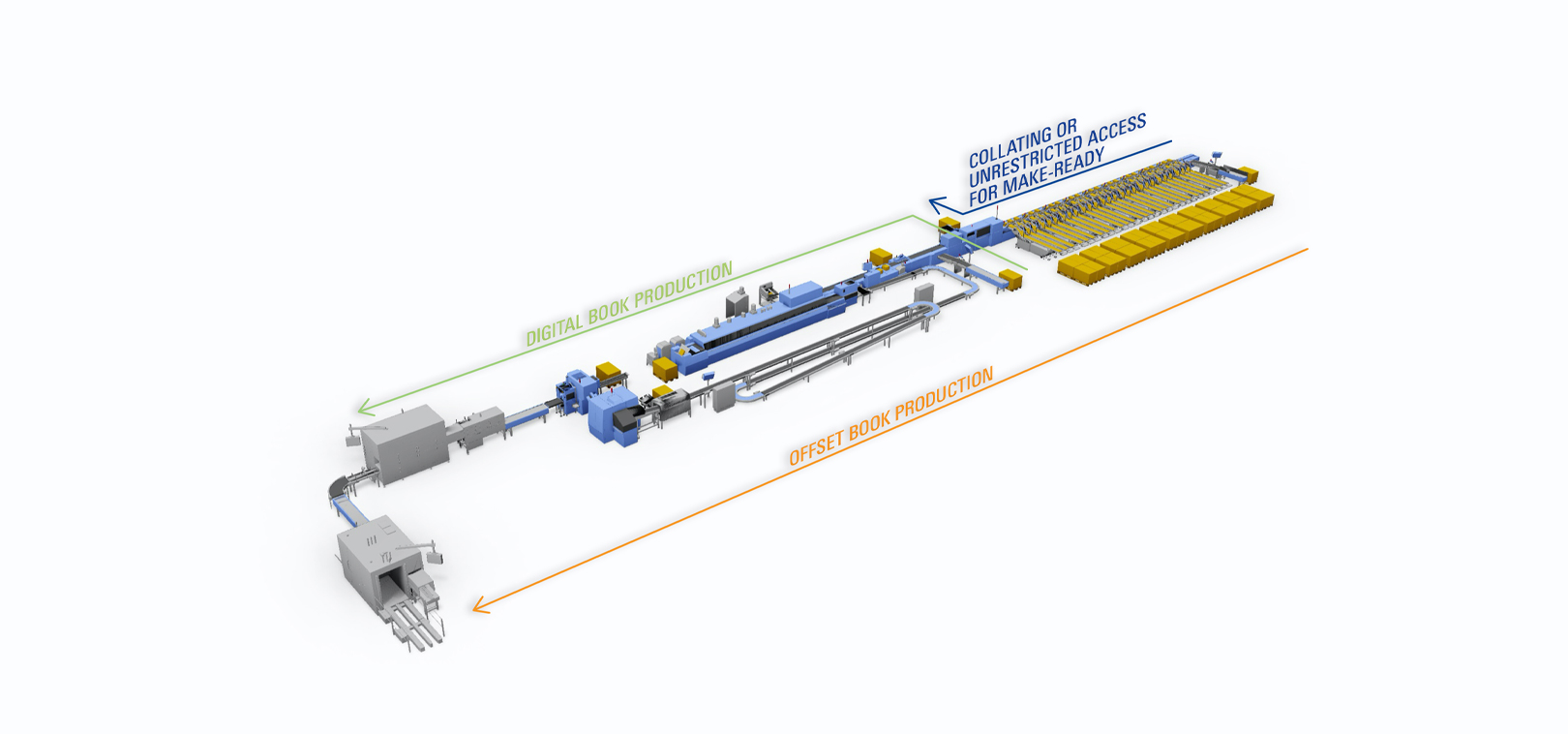

A typical example of this is the new Alegro Digital line of my customer Core Publishing Solutions in Eagan, Minnesota, which is part of Thomson Reuters Group. With 71 meters from the manual feed to the 27-station 3694 gathering machine, the Solit three-knife trimmer and the CB 18 book stacker through to the Pluton palletizer, it is not only one of the longest Alegro lines ever to be installed. It is also undoubtedly the most versatile perfect binding line in the world.

Israel Bonfil (machine operator at Core Publishing Solutions) together with Eric Olsen (Sales Manager at Muller Martini North America) at the signature stack feeder for digitally printed products, which is located as a special configuration between the gathering machine and the Alegro Digital binder in Eagan.

A multifunctional Alegro digital perfect binding line

Israel Bonfil (machine operator at Core Publishing Solutions) together with Eric Olsen (Sales Manager at Muller Martini North America) at the signature stack feeder for digitally printed products, which is located as a special configuration between the gathering machine and the Alegro Digital binder in Eagan.

A multifunctional Alegro digital perfect binding line

Core Publishing Solutions can produce digitally printed books on its Alegro Digital and gather signatures for sewn book manufacturing, or have full access to the gatherer to prepare the next job. Thus gaining a “free make-ready” and increasing output. The decoupling of digital book production from subsequent offset jobs has enabled a special configuration created by Muller Martini especially for the specific needs of printers needing high volume digital AND offset binding capabilities – hybrid manufacturing.

While the Digital Book Infeed had been traditionally placed at the beginning of a perfect binding line, it was placed between the gathering machine and the binder in Eagan, as well as at two other customers in the USA. This brings operators closer together, reduces the paper path and decouples the Alegro allowing it to perform in 1, 2 or 3 different entirely different production modes. Whether the jobs are short or long, offset or digital, the Alegro Hybrid can handle it. This capability is enhanced further by the automatic book thickness adjustment that happens seamlessly at up to 5,000 books per hour to ensure perfect quality and on-the-fly changeovers within the same format size.

A few figures clearly illustrate just how important this is: While three-fourths of all

jobs in Eagan are printed digitally, “only” 15 percent of all

pages are printed using this method. While an offset job is being prepared on the gathering machine, an average of 20 digital jobs run through the binder. “For us, this is the perfect hybrid application that has significantly accelerated our workflow and allowed us to stay up to speed in print finishing with the rapid growth and change in digital printing,” said Steve Zweber, Director of Core Publishing Solutions, recently.

Three machines in one

Three machines in one

But it is not the hybrid solution alone that makes Steve Zweber happy. In fact, Core Publishing Solutions, which produces more than 18 million Thomson Reuters books, brochures and updates of legal compilations every year – spread across more than 50,000 titles – and increasingly also prints products for the free market, has three machines in one in the Alegro Digital.

This solution reminds me of our PrimaPlus Tandem saddle stitcher launched a decade and a half ago. Thanks to two stitching machines joined together by a special connecting bridge, it allows our customers to either run two magazines with a smaller number of signatures in parallel or join all feeders together, to produce a magazine with a large number of signatures.

Then as now, Muller Martini is a leader when it comes to providing the graphic arts industry with market-compliant, future-looking solutions. And at our drupa stand in a few months' time, you'll also see that this will remain the case.

Kind regards,

Eric Olsen

Regional Sales Manager

Muller Martini North America