Even though softcover products are no longer printed in runs of hundreds of thousands, even millions of copies as they were a decade ago, high-performance perfect binding still has a hight significance. Because we believe in the future of high-quality leaflets and brochures, we are launching a new generation of perfect binders in three performance classes this fall: Publica PRO.

It is true that more and more phone books are being printed because of the competition from digital directories. In addition, extensive all-season catalogs from mail-order companies have often given way to periodically published, seasonal brochures in smaller print runs. But even if e-commerce has changed product marketing, there is still a marketing medium that no newsletter or attractively designed website can match. I'm talking about the haptic feeling and visual appeal of a product catalog printed on glossy paper.

First browse the catalog, then buy

For many people it remains something special to hold a beautifully printed catalog of 200 pages and more in their hands and to be able to look at it at their leisure anytime and anywhere. Just think of a top brand like IKEA. Haptic catalogs not only show how important the customers and the selling brand are, but the suppliers also help consumers to imagine the products at home and understand the benefits they offer.

According to studies, 75 percent of consumers make a purchase after browsing a catalog. So, if you ignore this marketing medium, you have only yourself to blame. Printed catalogs touch more senses than online advertising can. You can pick up a catalog at any time – even without an internet connection – and you are not distracted by other things. Catalogs are books that tell stories about brands.

An indispensable sales tool

A typical example of this is the tourism industry – even though it is currently suffering particularly from the Corona pandemic. Markus Flick, company spokesman for the Swiss market leader DER Touristik Suisse, recently wrote in an internet forum: "Regular surveys confirm that printed catalogs continue to meet a need of our employees with an advisory function as well as our customers. The digital offer is undoubtedly large, but it is also often perceived as confusing. Here, catalogs provide a valuable remedy for many people – they present recommended, customized products from experienced tour operators". And Christoph Huckele, Head of Marketing of the Swiss provider Knecht Reisen, underlines this statement: "In our eyes, a well-designed catalog is an indispensable sales tool at the counter."

Publica PRO with numerous innovations

In order to produce high-quality catalogs, many customers worldwide rely on perfect binders from Muller Martini. And since this fall, we have been offering them a new softcover system in the high-performance segment – the new Publica PRO generation – with modern machine design, simple operation, advanced technology and optimized processes. It convinces with a high net output, top quality, short changeover times, hardly any stoppages and little waste.

The successor model to the KM 412, which is well established on the global market with over 150 lines installed, offers numerous innovations.

Three performance classes

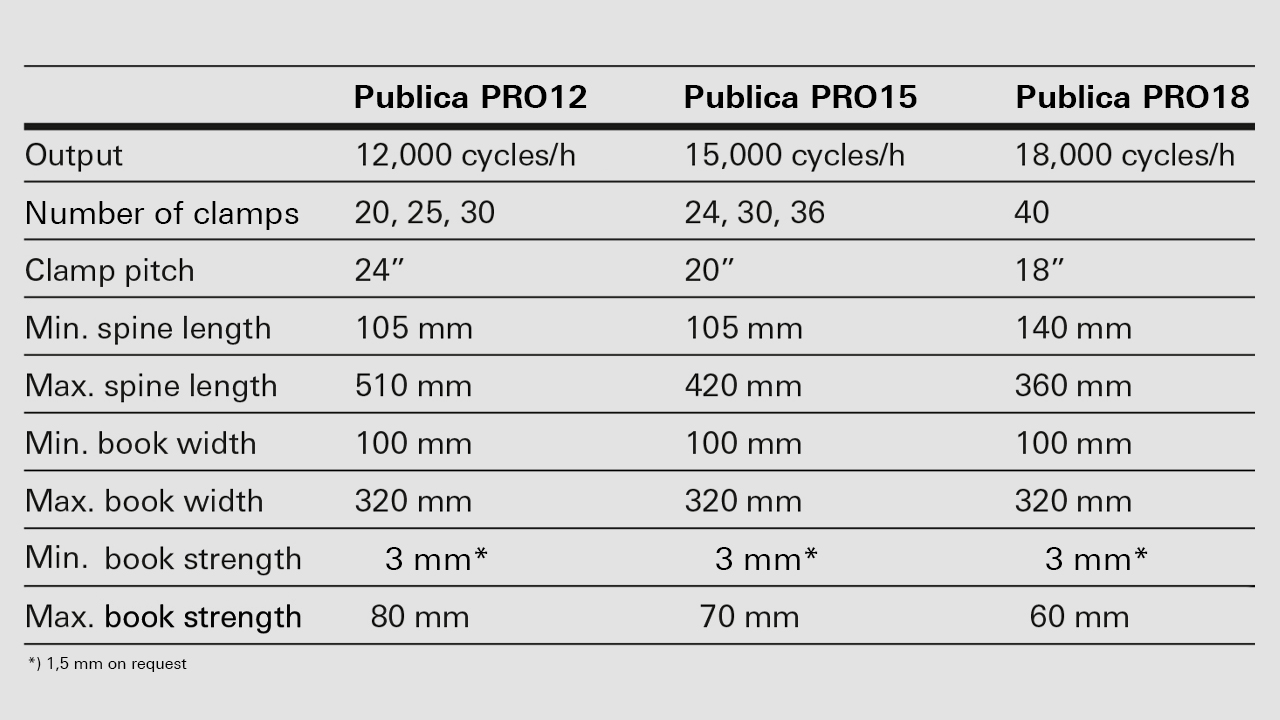

The perfect binding line, which is ideal for magazines, catalogs and high-volume publications, is available in three performance classes: 12,000, 15,000 and 18,000 cycles per hour (see graphic). The 12,000-cycle version can also be used to produce hardcover book blocks and spine strengthening is possible by using a lining station.

The Publica PRO, which is predestinated for single sheets and thin print runs, demonstrates its full flexibility with the ZU 842 suction-belt gathering machine, which has an output of 18,000 cycles per hour. It pulls off in the direction of material flow so that there is no wear and tear and separates the sheets via a suction belt in the running direction of the chain. The ZU 832 gathering machine (up to 12,000 c/h) is also available as an economical alternative.

Thanks to its modular design, the standard feeders up to 3 mm signature thickness (but extra feeders up to 5 mm are also possible as an option) can be easily replaced with a feeder for pre-folded signatures at the binding side or signatures with folded-in flaps as well as parallel folded or zigzag folded signatures that will be bound at their open side. The KK 842 card gluer processes a wide range of products (glued-in cards/booklets/CDs in covers /product samples). The electrostatic fixing of advertising media is also possible as an option.

The first Publica PRO is in production in Braunschweig – "Turn two into one"

Celebrating its 175th anniversary in 2020,

Westermann Druck GmbH recently invested in the world's first Publica PRO at its Braunschweig plant. The long-established German company is now concentrating on its two production sites – in Braunschweig and Zwickau – instead of three. Originally, Westermann Druck GmbH, which produces around 33 million softcover products annually with a focus on magazines, journals, catalogs and (school) books, planned to relocate a Muller Martini Corona perfect binder from the closed-down plant in Landau to Braunschweig (where 230 people are employed) and to produce on two lines there.

By means of a detailed business plan, however, we explained to our customer that a new investment in state-of-the-art technology is much more economical than operating two older lines. The slogan "Make one out of two" convinced the company, and so the choice fell on the Publica PRO15. In addition, an 18-station ZU 842 gathering machine was installed, while Westermann relied on existing (Muller Martini) systems for the peripherals.

What´s true for Westermann may well be true for many bookbinderies worldwide in my opinion: they often produce with older perfect binders with long make-ready and short cycle times. For them, "Make one out of two" is the right slogan – and the Publica PRO is the ideal solution.

Sincerely,

Your Lukas Budde

Product Manager at Muller Martini in Rahden