The New Primera MC Will Boost Micropress’s Productivity

06/06/2016

Micropress Printers in the English village of Reydon has relied on Muller Martini print finishing systems since the ‘90s. At drupa that close partnership continued with the signing of a contract for a Primera MC saddle stitcher.

“Replacing our printing presses and print finishing systems every seven to eight years is part of our company philosophy,” says Managing Director Mike Cross. In August, Micropress will therefore commission a new Primera MC with a cover feeder, four flat pile feeders, two vertical pile feeders and a Perfetto compensating stacker to replace an eight-year-old Prima. “We see it as an advantage to have a good feeder mix”, says Production Manager James Cross, explaining the combination of flat pile feeders and vertical pile feeders.

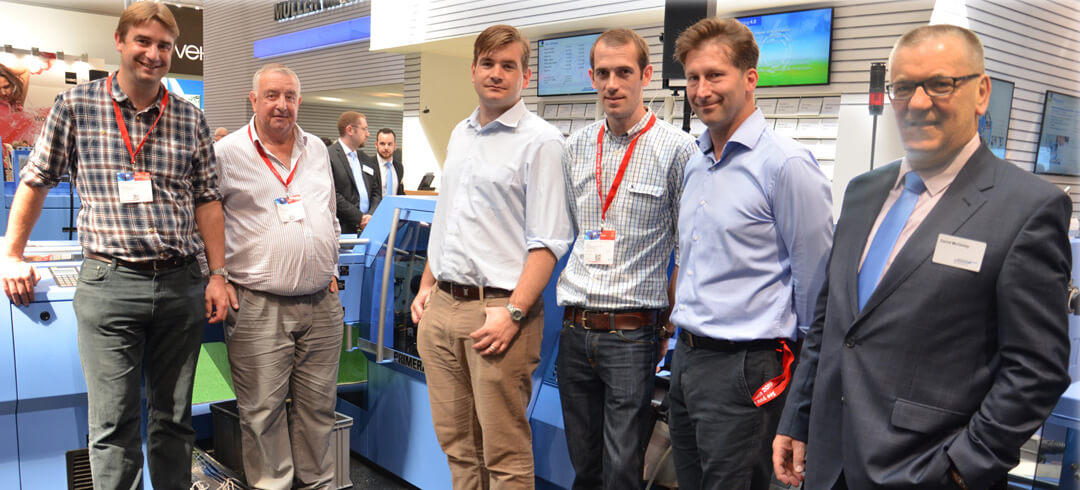

The Micropress team together with David McGinlay, Sales Manager at Muller Martini UK (right), in front of the Primera MC at the drupa booth.

Mike Cross explains that the company chose the Primera MC for three main reasons: “Thanks to the shorter make-ready times, we anticipate greater productivity, significantly higher production speeds and a considerable reduction in production waste owing to the high degree of automation.”

Micropress, which employs 130 people, chiefly produces magazines, brochures and booklets in a wide range of run sizes from 500 to 200,000 copies. Since the '90s, the family business has relied on Muller Martini equipment for saddle stitching and perfect binding (it currently uses an Alegro manufactured in 2013 for the latter). “Over all those years, we’ve established a strong relationship based on trust, so it was clear to us that our new saddle stitcher should again come from the technology leader,” says Mike Cross.