PI 2061 We’ll Corporation Enters a New Market Segment

02/14/2017

We’ll Corporation in Ishikawa is getting a Finishing 4.0 solution. The Japanese company is entering a new market segment – the production of teaching materials – with the aid of a Muller Martini print finishing system consisting of a 42-inch SigmaLine with a SigmaFolder II, a SigmaCollator and SigmaControl and an Alegro Digital perfect binder with a Solit three-knife trimmer.

We’ll Corporation, which specializes in direct mail and flyers in the commercial printing segment and uses several web printing presses, has not focused until now on the production of softcover books. As a result, the Ishikawa-based company, which was founded in 1979 and is a subsidiary of WELLCO Holdings Co. Ltd., currently only has a small perfect binder with a performance of around 150 cycles per hour. That, however, is set to change from 1 April onwards, when We’ll Corporation, which employs some 500 people at five different plants, will turn book production into one of its core business segments. For that purpose, the company has invested in two digital printing presses from HP (first in a T230 and then in a T490), as well as in a Muller Martini SigmaLine book production system consisting of a 42-inch SigmaLine with a SigmaFolder II (up to 16 pages), a SigmaCollator and SigmaControl, and an Alegro Digital perfect binder with a Solit three-knife trimmer as a supplementary near-line solution.

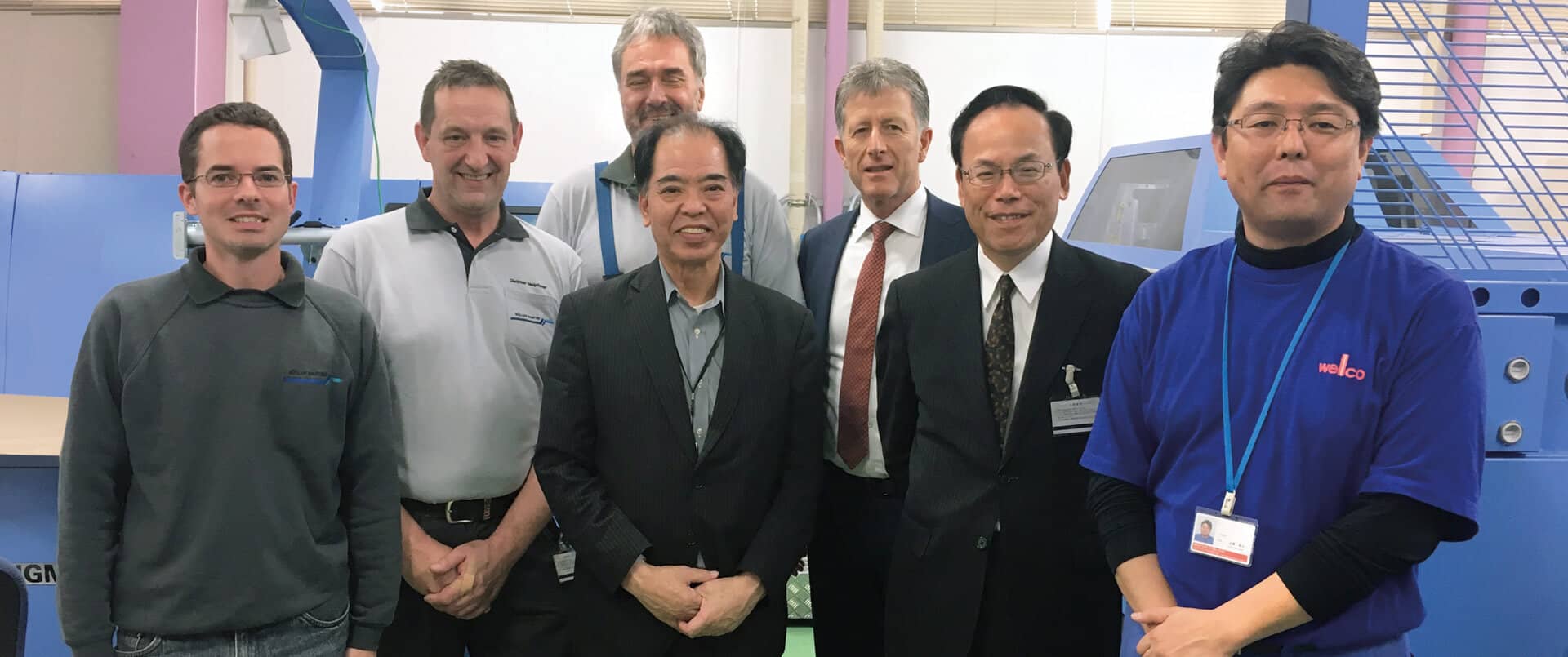

The Muller Martini installation team with Tsuneo Suzuki (center), Director of We’ll Corporation, and Bruno Müller (third from right), CEO of Muller Martini, in front of the new SigmaLine.

According to We’ll Corporation Director Tsuneo Suzuki, the company again opted for a Muller Martini system (We’ll Corporation has been using solutions from the Swiss machine manufacturer since 1996, including a Tempo saddle stitcher and a Primera saddle stitcher) based on Muller Martini’s convincing demo of the print finishing solution at drupa. “Eight people from our company saw Muller Martini’s demo at drupa and were so impressed that we purchased the SigmaLine that was presented at the booth there and then.” The We’ll Corporation delegation was particularly impressed by the fact that the SigmaFolder II is now also designed for printing speeds of 1,000 feet per minute, since We’ll Corporation is planning to print teaching materials in A4 and A5 sizes in runs of 500 to 10,000 copies for some 100 school classes a month.

The SigmaLine II and the Alegro Digital ensure the seamless processing of products from the HP T490 for the production of both long and short runs. Thanks to the Connex.LineControl workflow system, which acts as a single central control unit for job management, We’ll Corporation will simply need to create a PDF. The SigmaLine II will take care of everything else in a fully automatic and touchless manner, i.e. imposition, plausibility checking, optimization of the job sequence, and parallel loading of the printing press and the SigmaLine.

Fully automated and touchless production processes require significantly less personnel, allow for shorter setup times and generate less production waste than conventional methods. Tsuneo Suzuki explains that there is greater emphasis on impeccable in-line print finishing because “we have very high standards in terms of the quality of our finished products and new production methods”.