Hunkeler Innovationdays: Müller Martini zeigte Finishing 4.0 in Reinkultur

02/23/2017

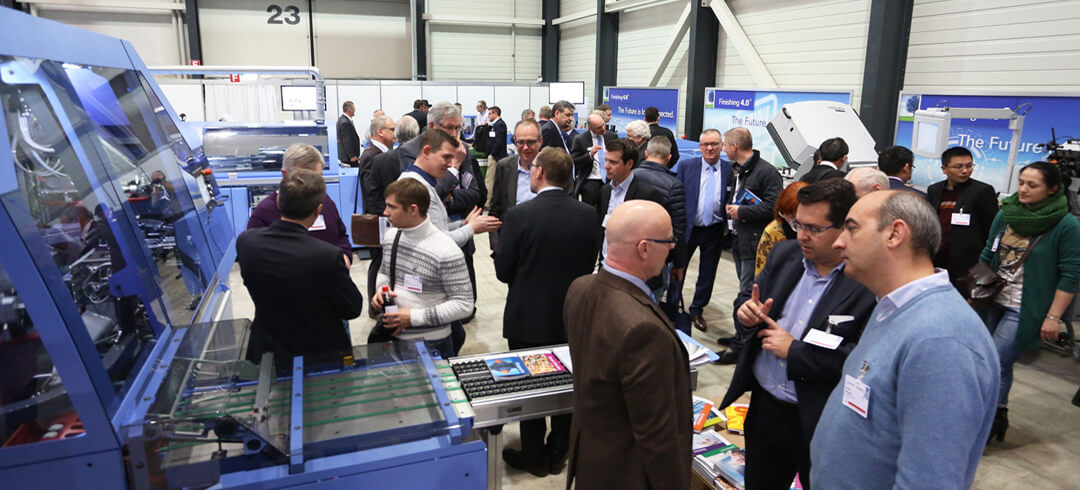

Muller Martini’s booth proved highly popular during the four days of the Hunkeler Innovationdays trade fair in Lucerne. As the epitome of Finishing 4.0, visitors from across the world experienced live the world premiere of connectivity between Hunkeler’s roll-to-stack line and Muller Martini’s Connex data and process management system, as part of a combined run of one line for softcover products, just like with Muller Martini’s Vareo perfect binding line.

“The connection of the Connex system to a Hunkeler roll-to-stack line in Lucerne was an important workflow milestone in Muller Martini’s systematic development of the Finishing 4.0 philosophy,” concluded Volker Leonhardt, Sales and Marketing Director at Muller Martini Print Finishing Systems AG, after a successful appearance at the trade fair. “Enabling the connectivity of Connex with the systems of a third-party supplier for the first time in the field of print finishing represents a quantum leap in the graphic arts industry. The fact that our booth at Hunkeler Innovationdays attracted so many visitors on all four days demonstrates that Muller Martini has its finger on the pulse with its solutions for runs of one copy in softcover production with the Vareo perfect binder and the InfiniTrim three-knife trimmer and in saddle stitching with the Presto II Digital.”

Numerous visitors from across the world took great interest in the live production demos of perfect-bound and saddle-stitched products in runs of one copy at Muller Martini’s booth at HID.

Volker Leonhardt was delighted not only that the Muller Martini booth proved so popular with visitors but also that “this year Hunkeler Innovationdays had become considerably more international thanks to numerous visitors from the USA, Asia and the Middle East. That’s a clear sign that digital printing is also gaining a more international profile. Our compact solutions for products in runs of one copy reduce the barriers for entry to digital printing for digital arts companies.”

“Printing Is the Easy Part. The Secret Lies in Print Finishing”

Jerome Morkel, Managing Director of Tandym Print, made the long journey from Cape Town in South Africa to Lucerne. He noted that high finishing quality is “the key to all digital production”. He added: “By quality, I mean processes. Especially for ultra-short runs, it’s important to have as few manual interventions as possible. There should be an integrated, seamless workflow.”

During his visit to the Muller Martini booth, Jerome Morkel therefore focused on production processes in particular. “It was incredible to see the solutions for the future that the machine manufacturers were showcasing here. Now it’s down to the printing plants to take the next step and invest in the systems on offer. Since we plan to do so ourselves, Hunkeler Innovationdays was the ideal opportunity for me to expand my knowledge of the processes involved.”

For Joern Kalbhenn, Managing Director of B&K Offsetdruck GmbH in Ottersweier (Germany), Hunkeler Innovationdays was likewise an excellent way to gain an overview of all the applications in digital printing in a compact space. “I’m particularly interested in finishing solutions. Printing is the easy part. The secret lies in print finishing. As Muller Martini showed at its compact booth, highly automated production processes are now possible thanks to integration with workflow systems.”

Livonia Print: No Future Without “Connextivity”

Livonia Print in Riga (Latvia) is the first graphic arts company worldwide to connect Hunkeler and Muller Martini systems with the Connex data and process management system. “We view that as an important step towards our goal of full integration,” said Trond Erik Isaksen. The company founder and owner explained that “the removal of all barriers between our conventional and digital production is a top priority. Using individual machines for production without them being connected is outdated. That’s why I see no future for our industry without ‘Connextivity’.”

Livonia Print is integrating not only the new Hunkeler bookline and the new Océ digital printing press with Connex, but also the new Muller Martini Ventura Digital thread sewing machine and the new Muller Martini Diamant MC Digital bookline. “At a later stage we plan to integrate all our Heidelberg printing presses and print finishing systems with Connex. We expect the total transparency of all the connected machines to result in higher up-time and productivity and reduced production waste.”

Connex Presentations Attracted Great Interest

Just like the daily live production runs of personalized softcover school textbooks and various saddle-stitched products (personalized children’s coloring books, two different adult’s coloring books with variable section length and variable folding, variable page counts, barcode-based cover matching, and variable-thickness stitching and trimming of each product, a personalized hybrid catalog and an A5 guide to Lucerne), the Connex demos at Muller Martini’s booth in Lucerne proved highly popular with visitors. Not only were new Connex connectivity options with standard interfaces, namely Heidelberg Prinect, the HP SmartStream Production Center and Enfocus Switch, showcased, but also the new interface (making it even easier for users to create and edit new jobs) and the new Connex.Info 4.0.

PLEASE SEE HERE FOR FURTHER PHOTOS AND A VIDEO OF MULLER MARTINI’S BOOTH