Once Again Playing a Pioneering Role

27.06.2019

Printing house Laballery in the French city of Clamecy has excellent growth prospects thanks to a new SigmaLine/Alegro digital book production system.

In 2007, Laballery became one of the first graphic arts companies in Europe to invest in a SigmaLine digital book production system from Muller Martini. Now, the printing house, which is located in Burgundy, is once again playing a pioneering role after opting for a second SigmaLine with a SigmaFolder II, a SigmaCollator, an inline connection to an Alegro digital perfect binder and a Granit three-knife trimmer from Muller Martini.

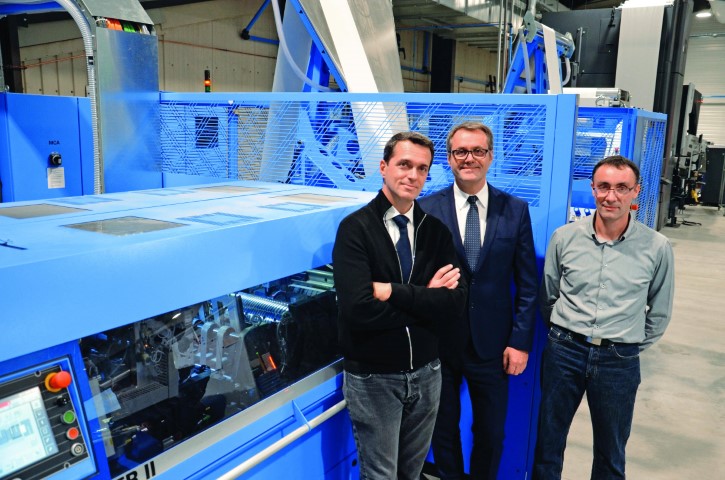

From the left: Hubert Pédurand (General Director), Philippe Michelon (Head of Sales at Muller Martini France) and David Perrain (Plant Manager/Chairman of the Board of Directors) in front of the new SigmaLine at Laballery.

From the left: Hubert Pédurand (General Director), Philippe Michelon (Head of Sales at Muller Martini France) and David Perrain (Plant Manager/Chairman of the Board of Directors) in front of the new SigmaLine at Laballery.

In doing so, Laballery has fortified its strong position on the French book market, where the company has increased its production volume over the last five years from five to 12 million copies. The company wants to increase by another 20 percent in 2019.

“France is back on the book producer map,” says Managing Director Hubert Pédurand, confident of the company’s strengths. In addition to two acquisitions the company has made, the latest technology from Muller Martini is a decisive reason for his confidence. The first SigmaLine, with a belt width of 30 inches and a printing speed of 200 meters per minutes is still in operation. As a result, all of the company’s processes, from digital printing to folding, gathering, perfect binding, cooling and cutting have been automated in a single line and carried out by one machine operator.

However, Laballery only uses the first machine to produce black and white books with runs of between 200 and 2,000 copies By contrast, the second SigmaLine, which has a belt width of 30 inches and a printing speed of 300 meters per minutes and has been in operation since last November, is also used to produce four-color books with print runs of between 2,000 and 10,000 copies. During the work process, it is linked to an HP T390 HD and controlled via the Connex Workflow System.