Müller Martini Presents World Firsts

at its Open House in Zofingen

On 21 September, Müller Martini invites customers to the Print Finishing Center in Zofingen, Switzerland, where it will demonstrate its latest innovations at this Open House. Among other things, new machine concepts from the areas of perfect binding and digital book production will be presented. During the "Factory Show", visitors will be able to have a look at how Müller Martini produces its high-performance products and solutions.

With the Open House, the Swiss manufacturer of machines for print finishing underlines its innovation skills while once again confirming its leading role in the market. "Events like our Open House are indispensable for engaging in dialogue with our customers and informing them about our latest innovations and the benefits they bring," stresses Volker Leonhardt, member of the group management at Müller Martini. "We expect around 80 visitors from the DACH region on 21 September, with a clear emphasis on Switzerland." In addition, the company is also welcoming international guests who will already be implementing concrete investment projects based on the newly presented products.

Book-of-One production to be seen live

Book-of-One production to be seen live

The presentation of the

SigmaLine Compact digital book production line at the Printing United Expo in the USA already generated a great deal of interest, especially among digital printers. The Open House now marks the sales launch of this new book production line. The system promises increased productivity in limited space, with lower personnel requirements and an equally low waste rate. Finishing 4.0 and sustainability can thereby be optimally combined in the production of books, brochures, and magazines. The SigmaLine Compact is designed for processing digitally printed rolls up to 22.5 inches and uses Müller Martine's patented air-knife technology. A further highlight is the greatly reduced set-up times - for example from four-up to six copies within a few seconds. This also enables a Book-of-one production, which can be experienced live in the Print Finishing Center.

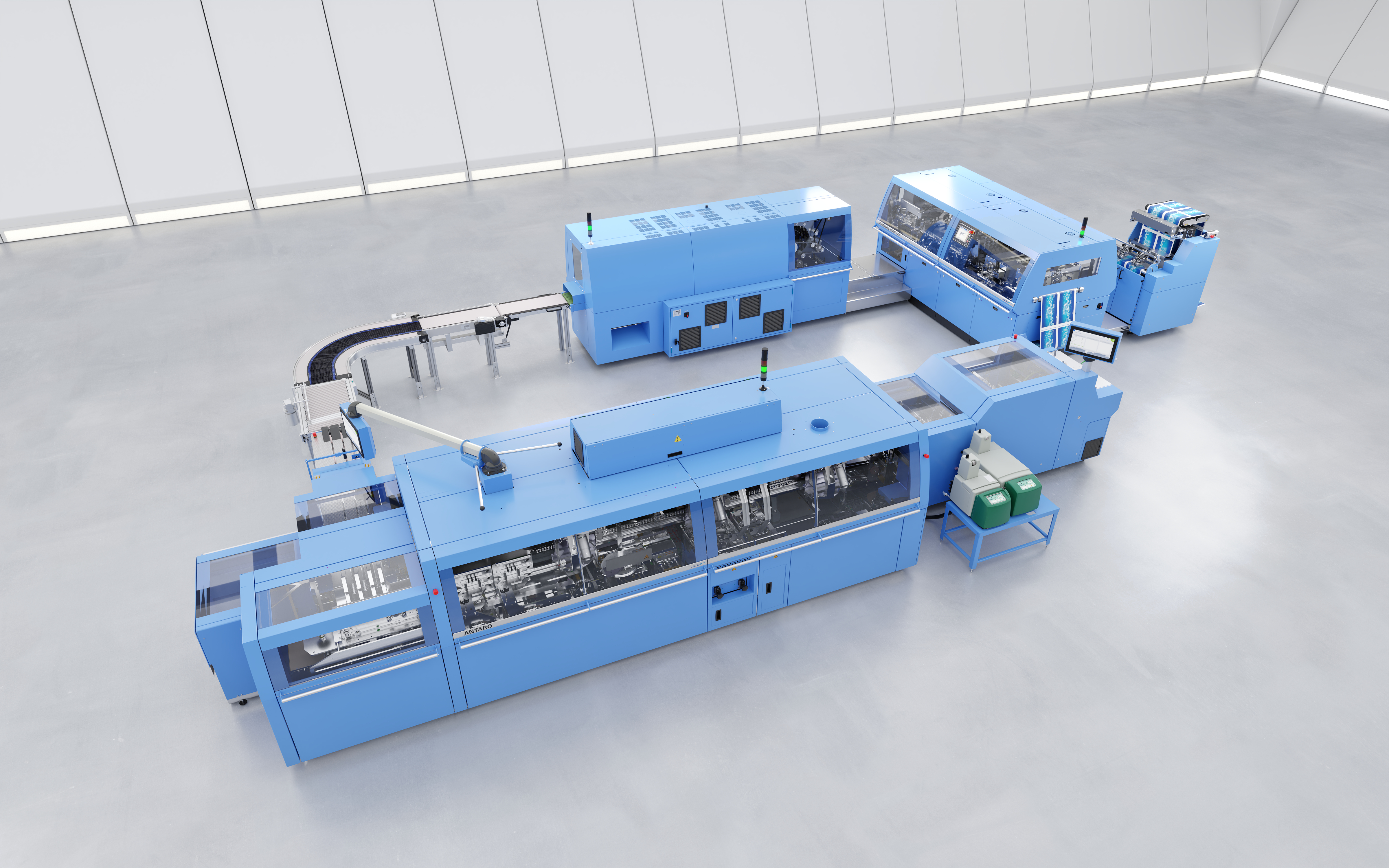

Antaro ensures versatility in perfect binding

The rapidly changing market conditions mean today's customers expect maximum versatility when investing in new production lines. This was also the main focus in the development of the new Antaro perfect binder. It combines the familiar and proven technology from Müller Martini systems and adds new functions. The Antaro processes all common types of book blocks such as signature stacks, pre-glued or thread-sewn book blocks, or single-sheet stacks.

The new perfect binder also demonstrates its total flexibility when it comes to end products. It can be used for soft-cover booklets as well as hard-cover book blocks, flex booklets, glued book blocks, or layflat booklets. The new perfect binder is available in two versions: the

Antaro Digital has a capacity of 2000 cycles/h, the

Antaro produces with up to 4000 cycles/h. Both perfect binders are available immediately.

Your partner in digital transformation

"We are very pleased to once again welcome customers to an Open House at the Print Finishing Center in Zofingen and to be able to present them with the Antaro perfect binder and the SigmaLine Compact book production line, two absolute novelties," says Volker Leonhardt. Both solutions will help raise print finishing to a new level of quality and productivity. The

Connex workflow, which controls all the equipment installed in the Print Finishing Center, will also be a contributing factor. "The Connex workflow solution, in tandem with the unique Müller Martini machines, forms the basis for supporting and accompanying our customers in their digital transformation with great consulting expertise."