Adhesive binding accounts for more than half of sales at Appel & Klinger, not least because the entire production chain and added value remain in-house – thanks, for example, to the Frontero face cut trimmer from Muller Martini. "In terms of quantity, however, saddle stitching dominates at our company," say the two managing partners Gerhard Appel and Michael Klinger. They took over the business in 2005 out of an insolvency, "because we sensed the great customer potential."

Arguably, Appel & Klinger covers the entire range from business cards and forms to notebooks and books. However, its core business is printed products for ministries (for the Free State of Bavaria as well as for the German federal government) and publishing houses. And their demands have been constantly increasing in the recent past – not only in terms of quality but also, and in particular, in terms of time slots.

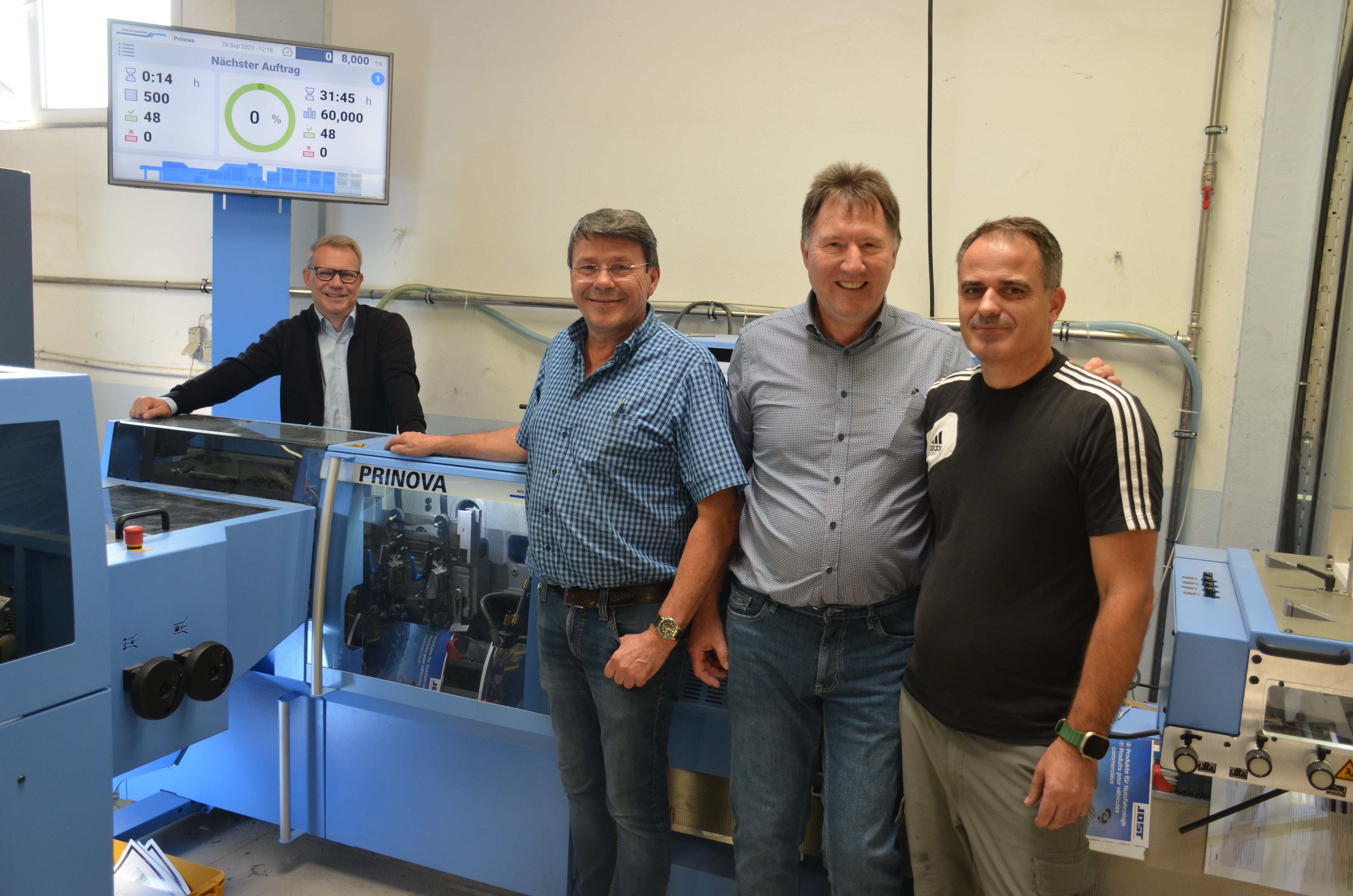

Gerhard Appel (second from right) and Michael Klinger (second from left): "We not only need a state-of-the-art and reliably running saddle stitcher, but also an innovative partner in terms of service and spare parts". Right: Lardim Ferizi (machine operator), left: Volker Keppler (Area Sales Manager Muller Martini Germany).

Gerhard Appel (second from right) and Michael Klinger (second from left): "We not only need a state-of-the-art and reliably running saddle stitcher, but also an innovative partner in terms of service and spare parts". Right: Lardim Ferizi (machine operator), left: Volker Keppler (Area Sales Manager Muller Martini Germany).

"We need an innovative partner"

And that in turn requires shorter set-up times. Appel & Klinger has therefore retrofitted two of its presses with LED drying to enable it to produce even faster, and last July it put a new Prinova with six flat pile feeders and a turnover feeder into operation to replace a saddle stitcher from another manufacturer. On this – and for certain jobs also on an ST 450 saddle stitcher – brochures, magazines, financial and annual reports with runs of between 50 and 150,000 copies are stitched at an average of 4,000 to 5,000 copies per job and with a high degree of format variability from small products to A3.

"We not only need a state-of-the-art and reliably running machine, but also an innovative partner in terms of service and spare parts. That's why we chose the global brand Muller Martini," says Gerhard Appel.

Compact layout, ASIR PRO, large screen display, servo drive

Michael Klinger, on the other hand, is particularly enthusiastic about the Prinova's new technological features, in addition to its smooth running and compact layout ("it takes up very little space"). In addition to the ASIR PRO camera system, which recognizes and compares the printed sheets by means of 1D/2D code and/or image comparison ("we can't afford to make any mistakes"), the convenient touchscreen and the large-screen display ("I like the big TV – I can see all the relevant production figures from a distance!"), he is particularly impressed by the servo drive for each feeder.

"That one really fascinates me. After setup at the push of a button, I hardly need to intervene. We were able to shorten the set-up time by 40 percent this way, and product stability is a lot better than with the previous model. The ease of setting up a machine has become a decisive argument, not least in view of the shortage of skilled workers."

With the Frontero face cut trimmer from Muller Martini, Appel & Klinger can produce cover flaps for softcover products in a single pass, thus increasing the value chain.

With the Frontero face cut trimmer from Muller Martini, Appel & Klinger can produce cover flaps for softcover products in a single pass, thus increasing the value chain.

Important signal to customers and employees

By investing in the new Prinova, according to Gerhard Appel, the company that employs 35 people in two-shift operations five days of the week, has not only increased its flexibility, but is also sending an important (safety) signal to customers – and to its own staff. "We are underlining that we believe in the future of printing."

The fact that Appel & Klinger is so successful is not only due to its wide range of printed products, 80 percent of which are offset (on five presses) and 20 percent of which are digital (on four presses/two each in black/white and colour), but also because of innovative products. For example, the Bavarian company – which has already relied on a Bravo saddle stitcher from Muller Martini and, in addition to the Frontero, also has a Granit three-knife trimmer and a Uni stacker from Muller Martini – specializes in barrier-free data generation in a profitable niche segment. In this case, reformatted data for the visually impaired or blind is supplied in addition to the printed product.

Learn more about the Prinova saddle stitcher in this video.