After first presenting the SigmaLine digital book production system at drupa 2004, Muller Martini is now offering a software solution for digital page assembly as well. Muller Martini worked with partners in this area for many years, but since 2017, it has developed its own solution, the Connex imposer module.

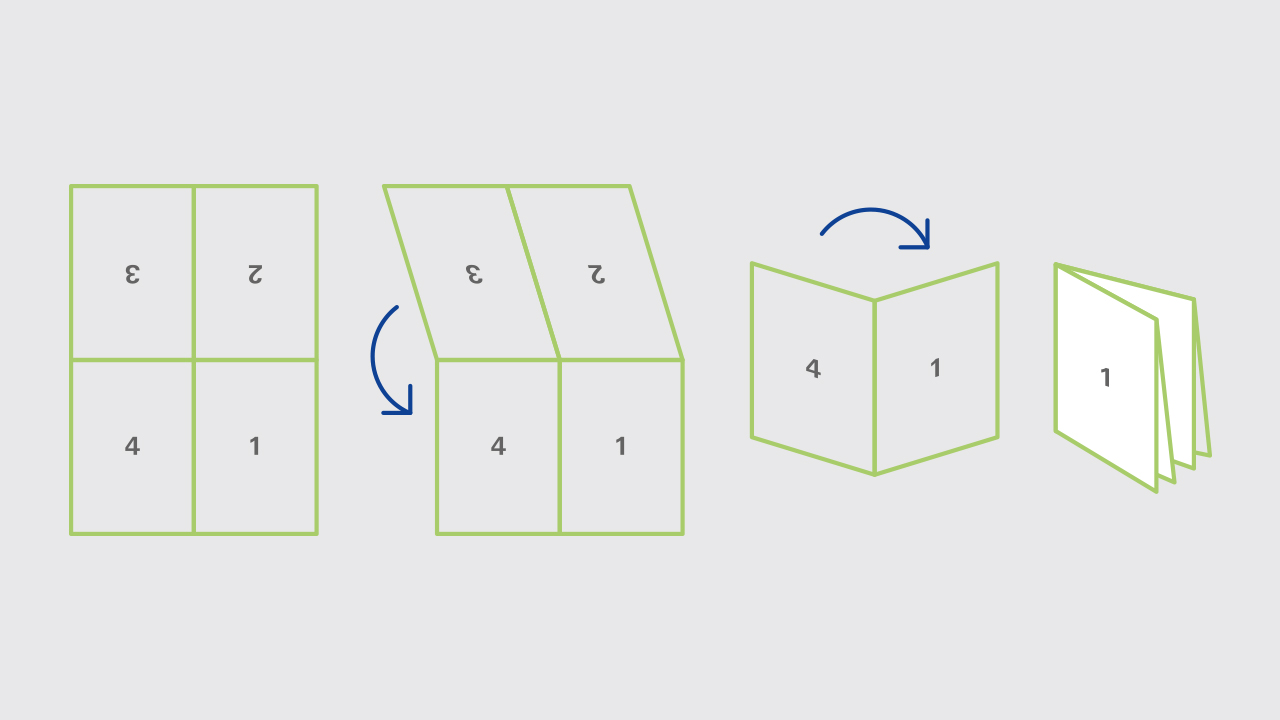

What is digital page assembly? Books are not printed on A3 sheets of paper which then contain four of the book’s pages. Doing so would be a labor-intensive production process. Instead, books are printed on sheets of paper up to 286 cm wide. These sheets are then folded to form a signature with up to 96 A4 pages.

With page assembly, the arrangement of the pages is specified on the individual sheets during the pre-press stage. Previously, page assembly required the use of mounting foils the same size as the signature. The corresponding films (transparent foils showing every element that had to be printed, similar to a photo positive or negative used for film) were affixed to each page using transparent adhesive strips or liquid film adhesive.

In addition to the films for the individual pages of the printed matter, printing marks such as register marks, reading marks, cutting marks, folding marks, printing registration marks and color control strips were also inserted. Only a few specialists were capable of carrying out this manual process.

Nowadays, page assembly is carried out using computer programs. It is referred to as digital page assembly or “digital imposition”.

While it may sound easy to place a couple of pages on a signature and then to print the signature, there are some points that need to be kept in mind. One example is when pages protrude. This happens when a signature is folded and the inside pages stick out past the edge of the folded signature.

If there were no compensation, the three-knife trimmer might cut the page numbers off the inside pages. So this effect is compensated by taking account of the paper thickness, the type of fold and the production method and either pushing the inner pages of the signature in or the outer pages out.

The Connex imposer module takes care of all these requirements (and many more). This solution is now being used by numerous customers with a SigmaLine implemented in LineControl Pro or as a standalone in connection with a Presto II Digital or for other special applications.

Connex imposer module offers six important advantages

With the Connex imposer module, which can be integrated in any customer workflow and carries out digital page assembly fully automatically, Muller Martini offers six important advantages.

-

Seamless integration: The solution can be integrated directly in the customer workflow via the digital job sheet and offers the highest level of performance without any manual steps.

-

Highest quality: With the Connex imposer module, Muller Martini provides imposed data that meets the quality requirements of offset printing. Customers receive a perfect digital signature.

-

Unusual setups: The Presto II Digital saddle stitcher from Muller Martini can process various signatures in a single production run. For example, one 12-page signature and three 8-page signatures can yield a 36-page product. The next product may involve a different combination of signatures and have only 24 pages. This requirement is highly complex and is only mastered by a few providers.

-

Page assembly for variable data: With digital printing, one product frequently varies from the next – either in terms of the content with the same number of pages or different numbers of pages. The Connex imposer module provides comprehensive solutions for this.

-

Plug and play: The solution is configured so that all brands and barcodes for all production steps are included in the solution and the customer can therefore begin production in the shortest amount of time.

-

Speed: The imposer module is one of the fastest imposers on the market and can, for example, impose on a just-in-time basis for a digital printing press that produces at a rate of 300 meters per minute.

Your

Andreas Aplien

Produktmanager Workflow

Müller Martini AG